Endpoint.Basestation.Data

Use Case Concrete Curing

Use Case

The use case Concrete Curing avoids extra costs during construction. Live Sample: New Building County Administration Office Landshut.

During the construction of the new building of the County Administration Office Landshut Germany, the construction company decided to monitor the surrounding conditions of the environment to avoid delays in the drying process or even prevent the concrete from vanishing. In many construction sites, winter time is a challenge in keeping deadlines and saving construction materials. Both harm costs.

Challenge of Concrete Curing

Live Sample: New Building County Administration Office Landshut.

During the construction of the new building of the County Administration Office Landshut Germany, the construction company decided to monitor the surrounding conditions of the environment to ensure the concrete curing process has no delays. Since the concrete curing process happened during the winter period 2023-2024 in Germany – Europe the temperatures reached -15 C. A challenge for the construction site of the new building since these conditions can delay the drying process or can have a fatal effect.

When curing concrete, temperature also plays a crucial role. The substrate must not be frozen under any circumstances. The colder it is, the more challenging it becomes for the concrete to cure. At 10 degrees below zero or colder, the chemical process necessary for the curing of ready-mix concrete may even come to a complete halt.

The construction company decided to use diesel heating systems to keep the temperature for floors at the required temperature level. TR1ton smart wireless sensor technology was used to overcome the challenges and monitor the process.

In the new building “County Administration Office Landshut”, an underfloor heating system was installed. After the installation, the underfloor heating was filled with water to ensure no leakage in the plastic pipes was missed. This had an additional impact in avoiding the concrete curing process to freeze the water in the pipes to ice. The ice would break the water pipes under the concrete.

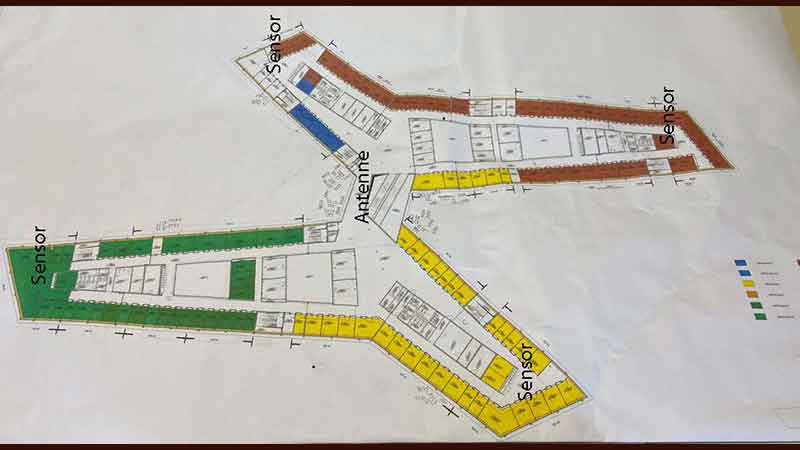

15 smart endpoints had been installed on the construction side and a single-based station to collect environmental conditions with temperature sensors and humidity sensors. The endpoint had been programmed with the threshold temperature and humidity value not to be reached. If the temperature threshold gets close, it is most likely that the diesel aggregate is not anymore working. In this situation, a WARNING was dispatched to a central safeguard to check on the diesel aggregate for refilling.

Picture: Construction site and the installation of endpoints and base station

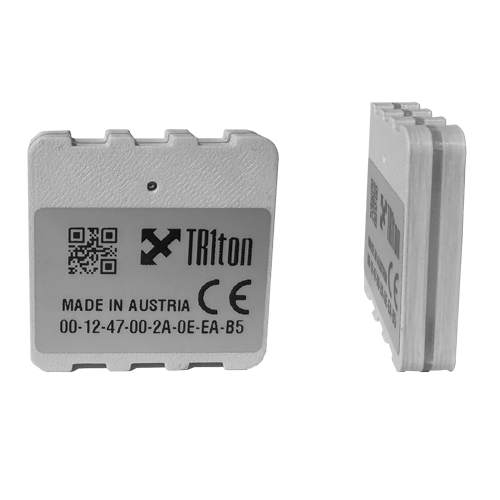

TR1ton Endpoint

| Sensors: 4 build-in sensors, all-in-one | |

| Transmission distance (LoS): 10km | |

| Frequency: 868 MHz | |

| Messaging: Smart triggers, warnings, alerts | |

| Size: 40mm x 40 mm x 10 mm | |

| Sensors: temperature, humidity, CPU temperature, signal strength | |

| Battery Life: up to 10 years in keepalive mode |

Temperature Sensors:

Temperature Sensors:

TR1ton endpoints come with a temperature sensor that can be programmed to deliver WARNING levels when certain values are reached, whether hotter or colder or even the ALARM levels (getting closer to the freezing point).

Humidity Sensors:

Humidity Sensors:

During the drying process, moisture evaporates. If the humidity sensor detects too high values the reason is most likely on overheating of the premises which can negatively impact the chemical process of the drying concret.

Picture: Endpoint monitoring at Landshut construction site

Remote Monitoring:

Remote Monitoring:

TR1ton’s remote monitoring solution allowed the construction company to have real-time inside of the concrete curing process (which is on average 21 -23 days). This helped to achieve deadlines and avoid extra costs.

Data Collection and Analysis:

Data Collection and Analysis:

By collecting and analyzing data from the sensors, trends, and patterns in the process during this weather condition can be identified. This enables future projects better planning and cost control.

Ensuring the proper concrete curing process protects construction sites to avoid delays, and protects sanitary installations. The live sample of Landshut saved the construction company time and money during hard weather conditions.

With TR1ton smart sensor technology made these goals reality and not only a dream.

Pictures: The structural construction work on the building of the new county administration office.

Project Link: https://www.dzpa.de/projekt/neubau-landratsamt-landshut/